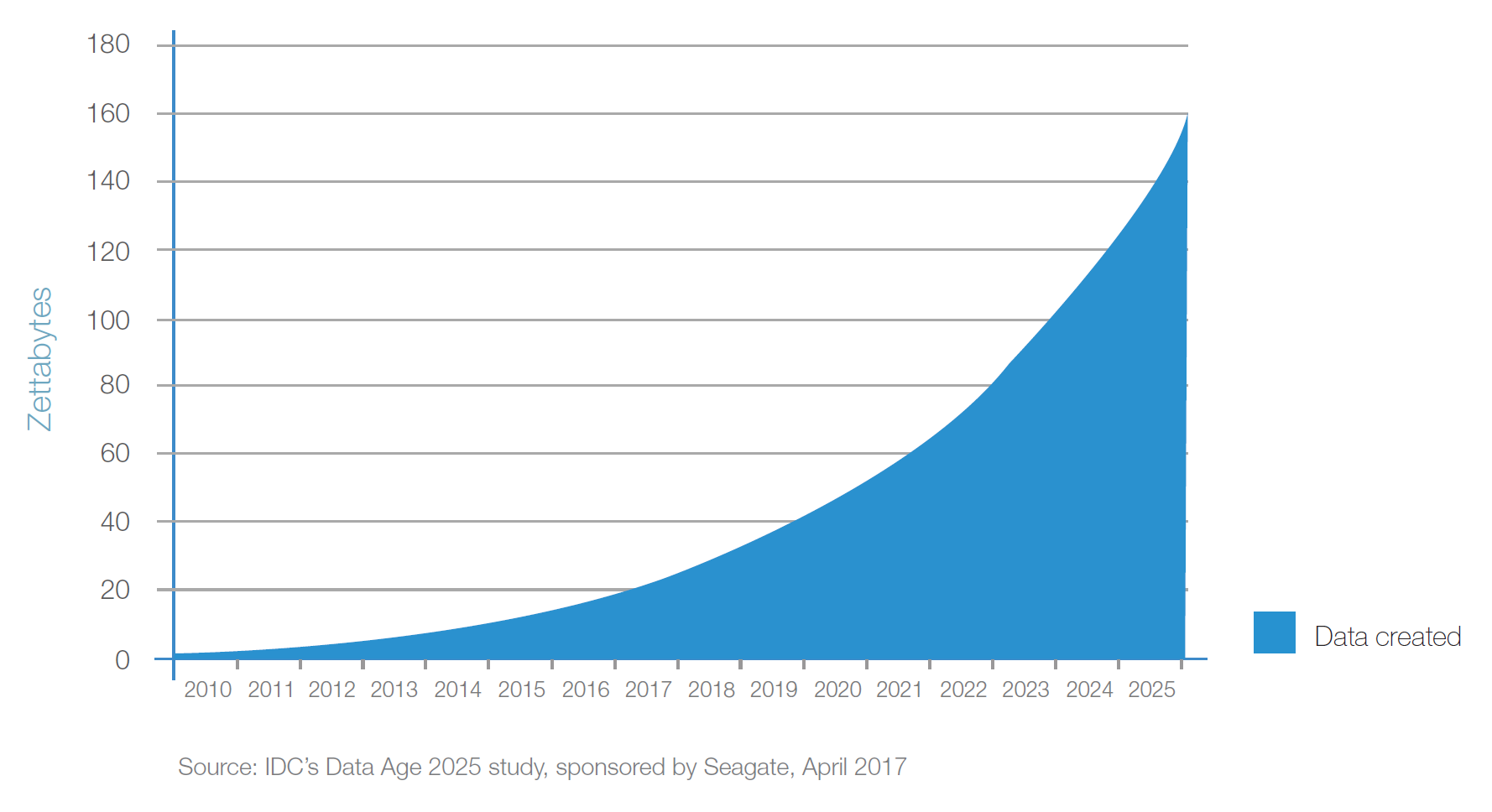

DATA GROWING EXPONENTIALLY

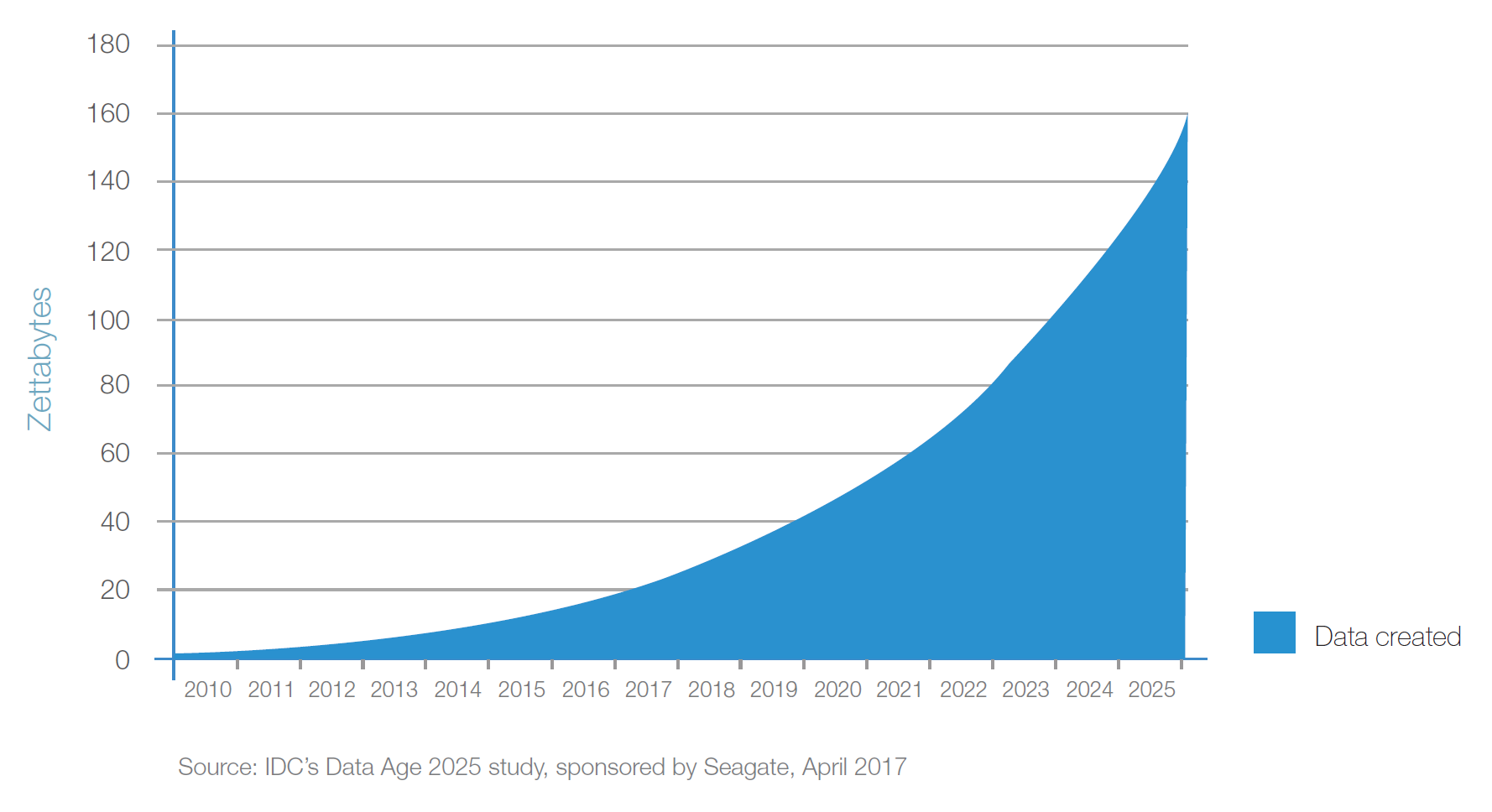

We truly live in the digital age. Like never before, every aspect of our lives involves data storage. In 2017, Seagate commissioned IDC to research the global datasphere. In their ensuing report, IDC identified five key areas that will govern data growth over the next decade: life-critical data, embedded systems (the Internet-of-Things), mobile and real-time data, artificial intelligence, and security. They conclude the amount of data created in 2025 will reach a staggering 163ZB (zettabytes, or trillions of gigabytes), which is ten times more than in 2016:

Figure 1: Annual Size of the Global Data Sphere (from Data Age 2025: The Evolution of Data to Life-Critical)

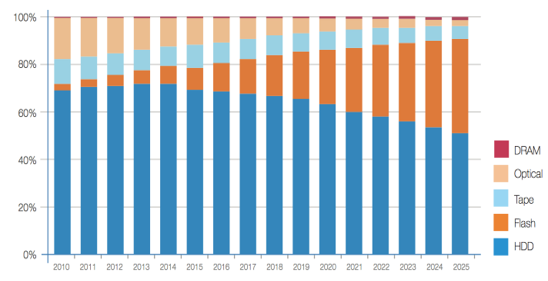

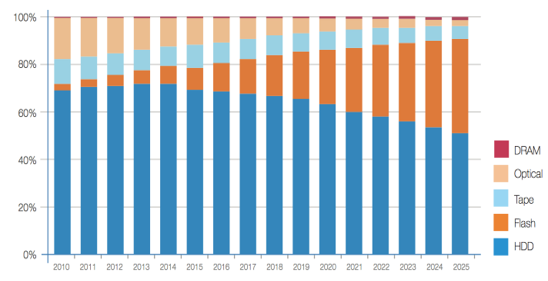

To give one an idea of the enormity of this data, storing all 163ZB would require 16 billion 12TB HDDs. Thankfully, even though that much data will be created, not all will need to be retained. Much of it will be used only once or twice, and then replaced by smaller metadata. Even so, IDC projects that 19ZB of storage capacity must ship through 2025 to meet the demand. And roughly 60% of this (or >11ZB) will still use HDDs:

Figure 2: Enterprise Storage By Type (from Data Age 2025: The Evolution of Data to Life-Critical)

This incredible demand for data storage really cannot be overstated. In his recent article, Luke Dormehl of Digital Trends explains,

“The reason for this is the unimaginable pace at which we currently produce data. Each day, around 2.5 quintillion bytes of data is created, courtesy of the 3.7 billion humans who now use the internet. In the last two years alone, a mind-boggling 90 percent of the world’s data has been created. With a growing number of smart devices connected to the Internet of Things, that figure is set to increase significantly.”

HDDs Are Here To Stay

Some analysts in the storage industry claim that SSDs will soon replace HDDs. While this might be true for applications that require extremely high number of operations-per-second, like transaction processing databases, it will likely never be true for mass data storage applications.

First, there is currently not enough flash production capacity to store all the world’s data; in fact only about 10% of the world’s data is currently stored on SSDs. And at the rate that the datasphere is growing, it is unlikely that flash production will ever meet the entire world’s demand. In fact Samsung, the world’s number one manufacturer of flash memory, is predicting that today’s flash production capacity of ~80 exabytes (or billions of gigabytes), will only reach 253 exabytes (0.253 ZB) by the year 2020. That falls far short of the 3000 EB needed by then. (See Samsung: NAND flash industry will triple output to 253EB by 2020.)

And secondly, HDD’s cost per gigabyte is only 10% that of SSDs, and these savings should continue, especially if HDD technology continues to evolve through innovation.”

Existing Technology Has Plateaued

Unfortunately current HDD technology is not evolving quickly enough to meet the exponentially growing demand. First, Perpendicular Magnetic Recording (PMR) technology is approaching its limits. The biggest recent gains were achieved by increasing the number of platters.

“Newer technologies that use energy to assist the magnetic recording (e.g., Microwave Assisted Magnetic Recording, MAMR, and Heat Assisted Magnetic Recording HAMR) continue to be delayed with no clear timeline in sight.”

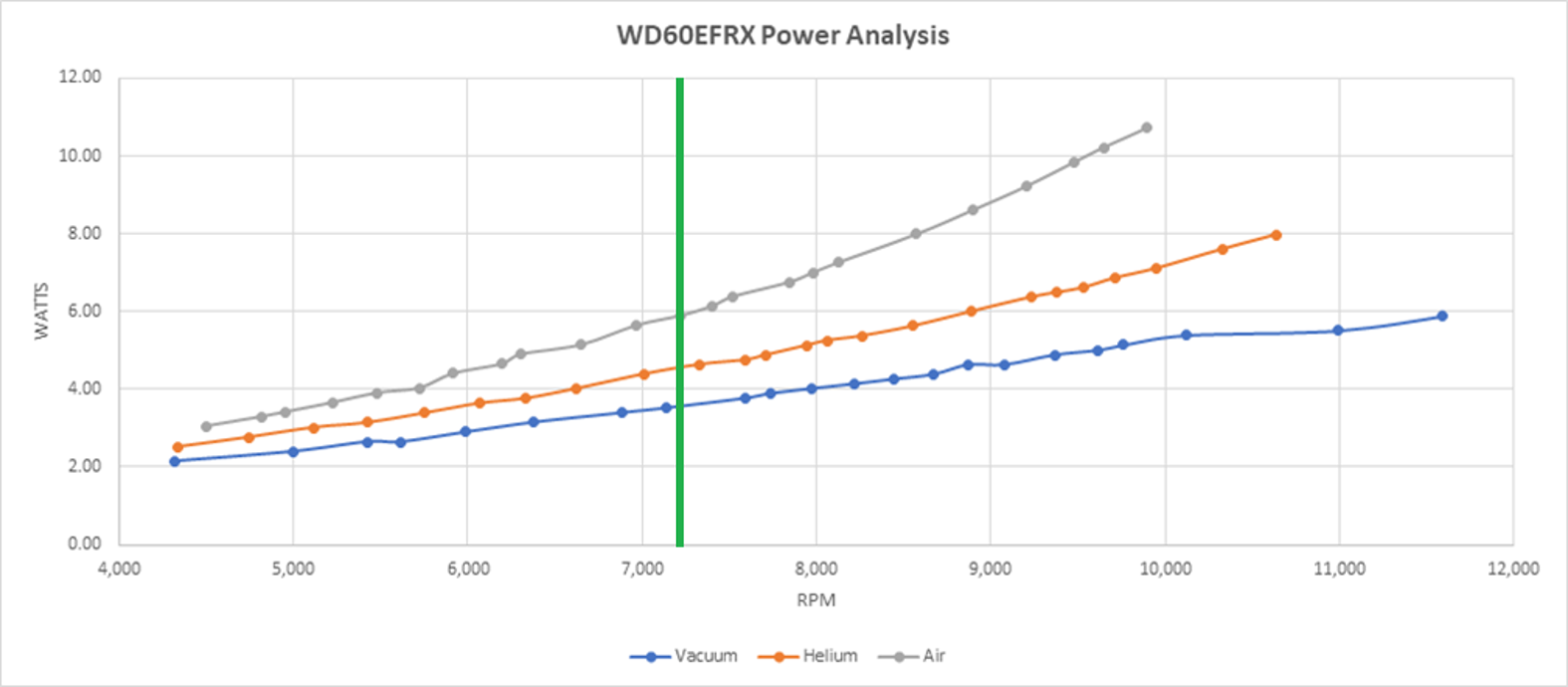

Air-Bearing Prevents Evolution

At L2 Drive, we believe the limiting component is the continued reliance on the air-bearing. Invented by Bill Goddard at IBM in 1956 (he called it an air-head), it has been central to HDD design for the past 60 years. It does solve a critical issue for drive operation, namely getting the read/write head to follow the disk surface closely enough so that data can be written and read reliably. It does so passively, by balancing the aerodynamic lift against the down-force, resulting in a dynamic but predictable fly-height. However, even though the head flies above the disk surface most of the time, it does touch the surface periodically. In order to protect the head and disk from damage during these touch downs, protective coatings or treatments are required on both head and disk. These coatings limit the ability to minimize magnetic spacing of the head and disk.