Tom Coughlin, Coughlin Associates, Inc.

The world’s demand for information continues to grow at an exponential rate, driven by IoT, AI and big data analytics, as well as higher resolution images and higher frame rate video. And all that information needs to be stored somewhere. While many applications are turning to flash memory, there is still a real need for cost effective storage, especially in the cloud.

Hard disk drives (HDDs) remain the best answer. They are much less expensive for mass storage of data than flash memory ($40/TB vs. $250/TB for SSD), and their latency and bandwidth make them ideal for near-line storage. Indeed, most of today’s data, including data stored in the cloud, is stored on HDDs (about 737 exabytes shipped in 2017 vs. 88 exabytes for SDD).

However, HDDs are facing a technological roadblock. While capacity has grown by 9 orders of magnitude since HDDs were introduced in 1956, that rapid and consistent growth has now slowed. Today’s growth in areal density (the amount of information that is stored on a unit of disk surface area) is less than 15% annually, compared to more than 30% for flash memory capacities. HDD technology needs to make some fundamental improvements to maintain its price/performance advantage versus other storage technologies like SSD and tape.

A new startup, L2 Drive, believes its vacuum drive technology is the answer. By completely removing all gases (air or helium) inside the drive enclosure and replacing the traditional flying heads design with a fully active z-actuator, L2 Drive estimates that it can further reduce the gap between the heads and the magnetic media thus increasing HDD capacities by up to 4X and enabling HDDs capacities as high as 50 TB or more.

HDD Background

A typical high capacity nearline hard disk drive is shown in the image below[1]. Much of the recent gains in storage capacity for these near-line HDDs has been through increasing the number of disks and heads in each drive unit, rather than higher areal densities. Currently these drives have up to 8-9 platters to achieve 14-16 TB storage capacity.

In a hard disk drive the disks rotate, driven by a spindle motor. During operation, as the disks spin, magnetic heads attached to an arm are moved across the disk surfaces using a rotary actuator. The heads are moved to discrete circular tracks on the disk surfaces. The write element in the heads can write information in the magnetic layers on each surface of the disks along the tracks or read information off the tracks.

To increase the amount of information that is stored on each disk surface, manufacturers have to devise new ways to store more bits along each track (commonly referred to the linear density) and increase the total number of discrete tracks on each disk surface (usually called the track density). Multiplying the linear density by the track density gives the areal density. Current drives can store information at a linear density of about 3000KBPI (Kilo-bit-per-in), and a track density of around 400KTPI (Kilo-tracks-per-in), for a total areal density of 1.2TBI (Tera-bits-per-square-inch).

There are many critical factors that impose practical limits on both the linear density and the track density. For the linear density, these factors include the total spacing between the write/read elements and the magnetic media, the physical properties of the magnetic thin films that store the data as well as the capabilities of the drive electronics. Of all these factors, the heads to media spacing (HMS) is the most critical. Historically, this distance was kept at about 60% of the length of the bit cell. Increase the HMS and the writer will not have enough strength to switch the magnetic grain and the reader will not be able to reliably distinguish one bit from the adjacent ones.

The main factor limiting the number of discrete tracks per surface is the actuator arm’s ability to “stay on track” as the disks spin at high RPM. In fact, as the disks spin, they generate winds in excess of 60 miles per hour inside the HDD enclosure. These turbulent winds cause the edges of the disks to flutter (vibrate up and down) and are constantly pushing the actuator arm off track. This limitation to track following has kept the track densities at the current values for a long time. Recent advances in “dual stage” actuator arms have managed higher track densities but at the cost of added complexity.

The industry has been pursuing ways to increase the storage capacity of hard drives in order to meet demand and for HDDs to remain competitive with other digital storage technologies. Let’s look at some of these approaches.

HDD companies are pursuing various forms of energy assisted magnetic recording as a solution to increase the linear recording density. These approaches involve using lasers (heat assisted magnetic recording, or HAMR) or microwave generators (microwave assisted magnetic recording, or MAMR) to “soften” a high coercivity magnetic media so it can be written using conventional magnetic recording heads. Implementing these technologies in a storage device that will last for years of use has been difficult to accomplish, but the first HDDs using these technologies may be coming soon.

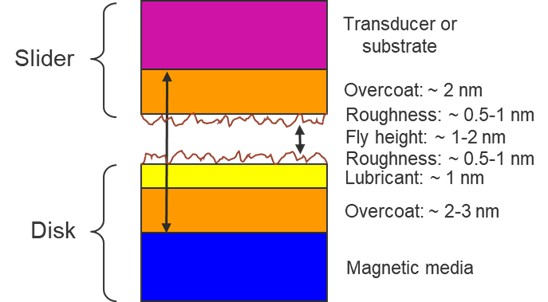

For either HAMR or MAMR to achieve a much higher density magnetic recording there is a continued imperative to decrease the total magnetic spacing between the read/write elements of the head and the magnetic layers on the disk. In today’s HDDs the read/write head floats only a nanometer or two above the disk surface as shown in the figure below[2]. However, the total distance between the write or read transducer of the head and the magnetic disk surface can be much larger.

In this figure carbon overcoat layers on the head slider and the magnetic disk as well as the lubricant on the disk surface must be added to the surface roughness of the head and disk to get effective (magnetic) spacing of 7 to 10 nm (up to 10X the flying height of the head). Regardless of the magnetic recording technology used, the density of information that can be written along the magnetic tracks is inversely proportional to the square of the magnetic spacing. For example, decreasing the magnetic spacing by half, opens up the possibility of magnetic recording at 4 times the current densities. For this reason, decreasing the overcoat thicknesses, lubricant thickness on the media as well as the surface roughness of the head and disk surfaces are extremely important factors in achieving higher magnetic recording density.

If the magnetic spacing between the heads and disk surfaces can be reduced, there would be additional benefits for HAMR and MAMR. The near field coupling of HAMR elements as well as the microwave elements in MAMR heads to the magnetic layer in the disk would both operate at significantly higher efficiencies if the magnetic spacing was reduced.

L2 Drive Technology

L2 Drive is proposing a number of new and innovative concepts for HDDs. First, instead of positioning the heads attached to flexible load beams attached to a multi-arm actuator, L2 wants the heads to be carried by a rigid suspension, called a z-actuator. The distance between the head and medium surface is monitored at 100,000 times per second, and adjusted at 15,000 times per second by a piezo-electric actuator, which is controlled by firmware in the HDD. This allows a very controlled distance between the head and disk surface and thus, combined with the second concept (evacuating the HDD, described below), eliminates head crashes. The 3D rotary head actuator is shown in the image below.

The second concept is to run the drive in a low pressure (or near vacuum) environment. Today HDDs are being made that are hermetically sealed and backfilled with helium (He). Evacuating all the gases from hermetically sealed drives can bring additional advantages. Air or even helium can cause flutter of the disks as they rotate through the gas, limiting how thin these disks can be and thus how many disks can be stacked in a hard disk drive package.

Removing the gas from the hard disk drive enclosure can also remove gaseous contaminants that cause corrosion of the disk surface, leading to less than smooth surfaces and potential damage to the head and disk from intermittent contact. The lubricant on the disk surface’s main roles are to protect the disk surface from contamination and to absorb heat and shock from occasional impacts from the heads. The protective carbon layers on the head and disk surface are there to prevent damage from occasional head and medium collisions.

Advantages for implementing L2 Drive Technology

The L2 Drive enables higher recording areal densities and more efficient energy assisted magnetic recording, prolonging head life and improving track density. Use of a 3D actuator in vacuum results in 25% less idle power consumption in vacuum compared to helium. Also the much reduced windage on the actuator arm in vacuum allows better track-following and thus higher track density.

An HDD under vacuum would avoid the gaseous contaminants that cause corrosion and thus the disk lubricant could be eliminated. The robust head disk interface (HDI) using the Z-actuator in vacuum improves the mean time between failure (MTBF) of the HDD. This might also allow removal or thinning of the protective diamond-like carbon layers on the heads and media. Removing the carbon protective layers combined with removal of the lubricant would decrease the head to media magnetic spacing significantly, allowing higher density information recording. In the image below2 the total magnetic spacing between the head and the disk surface is reduced to 2-4 nm (versus 7-10 nm).

This decreased magnetic spacing would result in much higher linear density recording and thus higher areal density. In addition, the coupling of the energy assisted magnetic recording energy sources (both HAMR and MAMR) would be greatly improved, leading to more efficient use of the energy sources. For HAMR in particular, this would result in much less heat generated during the write process, causing less stress on the recording head and thus longer drive life. Also, the more effective coupling of the energy source to the media will help prevent side writing, improving the track density achievable with energy assisted recording.

Likely there would need to be a regular way to continuously evacuate the HDD enclosure to make sure that gaseous contaminants don’t accumulate in the drive if the lubricant and protective layers were removed. L2 Drive has methods to incorporate continuous evacuation into the operation of the drives.

Technological Challenges

A 4x increase in density and capacity will not come easily. L2 Drive is aware of many challenges that must be overcome for this technology to realize its full potential. First the company must design, and implement, a robust control system to maintain the read/write heads at a constant distance from the disk without ever touching. This is similar to the servo mechanism already in used in HDDs for track following but the requirements for z-servo are somewhat tighter. There are also challenges with cooling the read/write heads in a vacuum. Paradoxically, early simulations show that maximum head temperatures might be lower for a head in a vacuum due to a major reduction in the power needed for the built-in heaters. In addition, the company’s simulations show that conductive heat pipes are quite capable of evacuating the relatively low amounts of power dissipated in the read/write heads especially if most of the ceramic slider is replaced with a good heat conducting metal.

Other challenges of which the company is aware are related to thinning of the media and head coatings in order to reduce the HMS. Such coatings are there to protect the head and the media from corrosive chemicals that might be present in the atmosphere or might outgas from other parts of the HDD. However, since the company is proposing that the drives operate under a hard vacuum, such corrosive elements will be rare; in addition, “getter surfaces” can be added to the HDD enclosure to attract and absorb any corrosive elements.

All in all, these challenges are not insurmountable and certainly worth the effort of resolving them given the potential 4x increase in areal density.

Conclusions

The L2 Drive technology provides several improvements over conventional magnetic recording in hard disk drives. The rigid Z-actuator allows for more precise control of the head to media spacing and combined with reduced disk flutter in a vacuum can eliminate head and media contact. This could allow thinner disks and more disks per drive. It also reduces the overall energy consumption of the drive, that would help reduce overall power consumption and cooling in data centers.

In addition, with no gases in the drive there are no gas-born contaminants and the disk lubricant and possibly the carbon protective layers on the disk and head surfaces can be reduced in thickness or eliminated, allowing for a much reduced magnetic spacing between the head and magnetic disk surface. This reduced spacing loss would allow much higher magnetic recording density along the track surfaces, providing much higher recording areal density and accelerating hard disk drive areal density growth and the storage capacity available in the drive.

In addition, closer magnetic spacing would improve the coupling of energy assisted magnetic recording transducers, making them more efficient, generating less heat and prolonging head life and allowing higher track densities, further enabling areal density growth. L2 Drive technology combined with HAMR or MAMR, could enable areal densities up to 4 TB/in2 and HDD capacities of more than 50 TB.

The L2 Drive technology deserves consideration by the hard disk drive industry. Incorporation of some of these patented technologies would help advance magnetic areal density growth, reduce HDD power consumption and help make any form or energy assisted magnetic recording successful.

About the Author:

Tom Coughlin, President, Coughlin Associates is a widely respected digital storage analyst as well as business and technology consultant. He has over 37 years in the data storage industry with multiple engineering and management positions at high profile companies.

Dr. Coughlin has many publications and six patents to his credit. Tom is also the author of Digital Storage in Consumer Electronics: The Essential Guide, which is in its second edition with Springer. Coughlin Associates provides market and technology analysis as well as Data Storage Technical and Business Consulting services. Tom publishes the Digital Storage Technology Newsletter, the Media and Entertainment Storage Report, the Emerging Non-Volatile Memory Report and other industry reports. Tom is also a regular contributor on digital storage for Forbes.com and other blogs.

Tom is active with SMPTE, SNIA, the IEEE (he is President-elect of IEEE_USA and active in the Consumer Electronics Society where he is chairman of the Future Directions Committee) and other professional organizations. Tom is the founder and organizer of the Annual Storage Visions Conference (www.storagevisions.com as well as the Creative Storage Conference (www.creativestorage.org). He was the general chairman of the annual Flash Memory Summit, the world’s largest independent storage event for 10 years. He is a Fellow of the IEEE and a member of the Consultants Network of Silicon Valley (CNSV). For more information on Tom Coughlin and his publications go to www.tomcoughlin.com.

[1] https://www.mobile-harddisk.nl/product/12440/8tb-seagate-exos-7e8-enterprise-capacity-sata-hdd-st8000nm0055.html?language=en

[2] HDD Fully Active Head Medium Spacing Control in Vacuum, Peter R. Goglia, Karim Kaddeche and John Wang, 2018 IEEE TMRC, L2 Drive